Quality Control

We believe that the best way to make sure that every single one of our products reaches you in an excellent working condition, is to check them thoroughly before they leave the factory. Therefore, each product undegoes a rigorous Quality Control checking process, some of which checks are detailed below.

Checking for correct operation

Firstly we mount the product on a purpose-made jig. The items are checked for square, then each of the panels are checked for tolerances and correct operation.

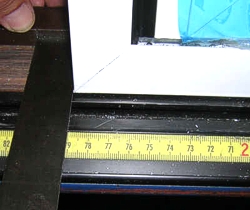

Checking dimensions

The dimensions are checked against the manufacturing details.

Checking mitres

All the mitre cuts are surveyed to ensure they are clean and smooth. Poor mitres are noticable and may allow water ingress.

Checking handles

Handles are checked for quality of finish and operation. The keys are used to check lock operation for smoothness.

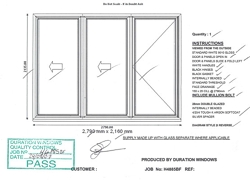

Signed off check sheet

Once the product has been checked and compared to the worksheet, it gets a green "PASS" stamp and is signed off by quality control.

Now that this product has passed quality control it will be wrapped up in several layers of bubble wrap and packing tape ready for delivery to our customer.